- Contact:Minister Xu

- Mobile:13841408476

- Tel:024-44837288

- Fax:024-44837004

- E-mail:xuming58@126.com

- Web:natashaterry.com

- Address:No.110 XiangHuai Road

Benxi Economic Development Zone

Liaoning Province

Innovative, Universal, and Modular: The New ProLink Condition Monitoring System From Schaeffler

20 May,2019

- The new ProLink condition monitoring system (CMS) offers maximum efficiency in machine and facility monitoring

- Unique: A plug-in field bus module ensures integration into every customer’s infrastructure

- Flexible scaling thanks to modular design

- Intuitive configuration with intelligent, machine-specific templates

- Universal gateway for Industry 4.0 solutions from sensor to cloud

Industry 4.0 applications require complex interlinking and allow intelligent data analyses for increased efficiency. Schaeffler has fully integrated these new requirements and options into the new generation of its multi-channel condition monitoring system. ProLink CMS is ideal for monitoring entire production facilities in a range of sectors that includes the paper and steel industries as well as for machine tools. The modular design and flexible integration into existing customer systems combined with the high level of signal and analysis quality that ProLink CMS provides mean that the system is easy for the customer to operate and delivers maximum efficiency in machine and facility monitoring. ProLink CMS is by no means confined to local implementation, however: It also provides a gateway for Industry 4.0 solutions and paves the way for digital services from Schaeffler.

Prioritizing customer benefits: Premium signal analysis without expert knowledge

ProLink CMS is very easy to put into operation, as the system requires no knowledge of any kind in the field of signal recording and vibration analysis. With the help of the intuitive configuration assistant, the customer enters only basic data for the components to be monitored via a web browser. Intelligent templates fill in all remaining information for the specific components, such as rolling bearings, motors and gearboxes, fans, and pumps. During the self-learning test phase in operation, ProLink CMS automatically defines the alarm thresholds for up to 100 operating points for each machine based on its speed and load conditions. Just like Schaeffler’s single-channel SmartCheck CMS, the ProLink multi-channel system provides the customer with high-quality and frequency-selective detection of bearing and gearbox damage, imbalance, and much more.

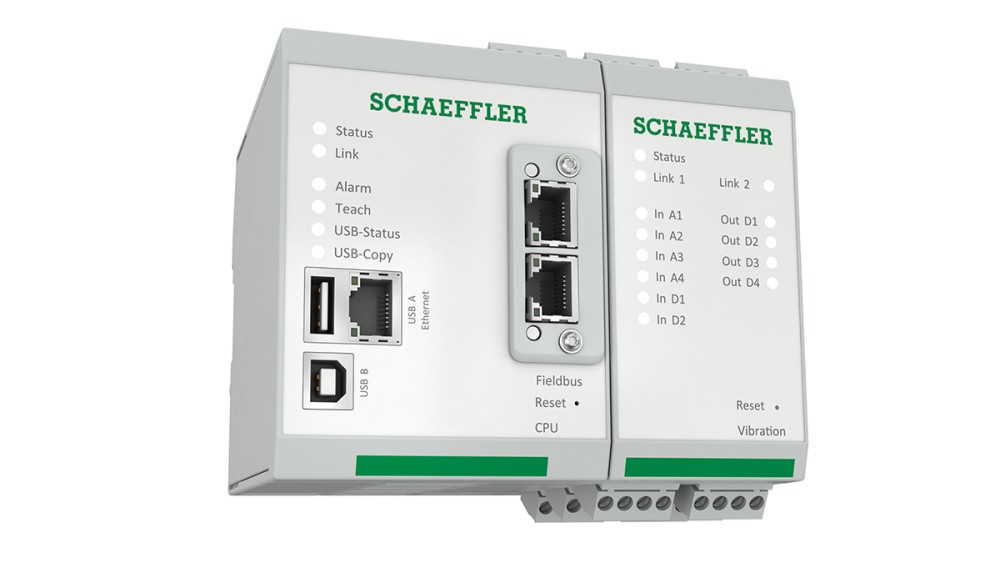

ProLink CMS comprises a main processor module for signal processing as well as a range of signal recording modules including a vibration measurement module that can have up to 16 channels. The modules are simply mounted on the switch cabinet’s top hat rail. An outstanding feature of the multi-channel CMS is that it can be universally integrated into the customer’s infrastructure using a plug-in field bus module. The system supports OPC/UA and Profinet as well as CC-Link IE, with further field bus protocols to follow.

An advantage for service providers and system integrators is that ProLink CMS allows them to operate multiple control landscapes on the market with a single hardware system. OPC/UA and MQTT are used for cloud communication. All of this means that the multi-channel CMS is the perfect choice for Industry 4.0 applications.

Gateway to digital services from Schaeffler

The customer can operate ProLink CMS locally and connect it to their machine control system via the field bus. Additionally, ProLink CMS provides the additional option of transmitting the preprocessed sensor data to Schaeffler’s service platform for more specific analysis via MQTT. Customers will have all of Schaeffler’s digital services – including the ConditionAnalyzer and load collective classification – at their disposal in the future via this interface. ProLink CMS can be used here as a universal gateway for connecting the sensor level with the control and management levels and even cloud applications. ProLink CMS therefore represents an excellent basis for mechanical and plant engineers to develop sector or even machine-specific Industry 4.0 solutions and thus offer their own added value models.