- Contact:Minister Xu

- Mobile:13841408476

- Tel:024-44837288

- Fax:024-44837004

- E-mail:xuming58@126.com

- Web:www.natashaterry.com

- Address:No.110 XiangHuai Road

Benxi Economic Development Zone

Liaoning Province

Better mapping and knowledge of minerals key to oil extraction

13 Feb,2019

Scientists in the US and Denmark have made breakthroughs which will improve our ability to extract oil. The first involves more accurate mapping of reservoirs, while the second throws a light on how oil clings to its containing rocks. Sean Ottewell reports.

Researchers at the Massachusetts Institute of Technology (MIT) Department of Civil and Environmental Engineering, with funding from Shell International Petroleum, have developed technology that can generate an accurate underground map that has the potential to significantly increase the amount of oil extracted from reservoirs.

The new technology uses the digital image compression technique of JPEG to create realistic-looking, comprehensive maps of underground oil reservoirs using measurements from scattered oil wells. These maps would be the first to provide enough detail about an oil reservoir to guide oil recovery in the field in real time.

"Our simulation studies indicate that this innovative approach has the potential to improve current reservoir characterisation techniques and to provide better predictions of oil-reservoir production. The hope is that better predictions ultimately lead to more efficient operations and increased oil production," said Behnam Jafarpour, a recent MIT graduate who is now an assistant professor in petroleum engineering at Texas A&M University.

Jafarpour and Dennis McLaughlin, the HM King Bhumibol Professor of Water Resource Management at MIT, published a pair of papers describing the technique that will appear in an upcoming issue of the Society of Petroleum Engineering Journal, as well as a third paper that appeared in the June 2008 issue of Computational Geosciences.

The spatial structure in geologic formations makes it possible to compress rock property maps. But JPEG compresses the many pixels in a detailed image down to a few essential pieces of information that require only a small amount of storage.

In the oil reservoir characterisation application developed by MIT researchers, a similar mechanism is used to provide concise descriptions of reservoir rock properties. The new technique uses oil flow rates and pressure data from oilfield wells to create a realistic image of the subsurface reservoir.

Petroleum extraction is expensive and relatively inefficient - sometimes as little as one-third of the oil in a reservoir is actually recovered through pumping. So engineers rely on enhanced recovery techniques such as water flooding to mobilise the oil. To guide this work, they make real-time predictions of subsurface variables, including oil saturation and pressure, but they're essentially working blindly.

The rock properties needed to make these predictions (for instance fluid conductivity of rock at a particular depth) can't be seen or measured. Instead, engineers infer geologic properties indirectly from seismic data and measurements taken at scattered wells.

"In a typical reservoir, millions of pixels are needed to adequately describe the complex subsurface pathways that convey the oil to wells. Unfortunately, the number of seismic and well observations available for estimating these pixel values is typically very limited. The methods we've developed extract more information from those limited measurements to provide better descriptions of subsurface pathways and the oil moving through them," said McLaughlin, lead researcher on the project.

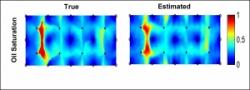

In a 36-month simulated oil-recovery process, McLaughlin and Jarfarpour's estimation approach accurately captured the main features and trends in fluid conductivity of a reservoir formation, demonstrating that the new technique is robust, accurate and efficient (Fig.1).

"Our next step - already in progress - is to test our idea in real oil reservoirs and evaluate its impact on oil recovery under realistic field settings," Jafarpour said.

Meanwhile, new Danish research may have come up with an explanation as to where and how North Sea oil clings to underground rocks. This explanation could turn out to be the first step on the way to developing improved oil production techniques with the intent of increasing oil production from Danish oil fields.

A research group at the Nano-Science Centre, part of the Institute of Chemistry at University of Copenhagen, has investigated drill cores collected from North Sea oil fields using an atomic force microscope.

Their investigations show that the spaces which contain oil have totally different surface qualities than expected from our knowledge of the minerals which make up the rock. The rocks which contain oil in the Danish part of the North Sea are primarily chalk - the same type of rock that the cliffs of Stevns and Mons in Denmark are made of.

Assistant Professor Tue Hassenkam led the research, whose preliminary results were published in Proceedings of the National Academy of Sciences (PNAS) in June. He says that this is the first time that investigations of this type have been carried out on chalk from an oil field in the North Sea.

"Previous investigations were carried out on the surface properties of pure mineral crystals. But our investigation has shown that this chalk has a different and more complex structure," says Hassenkam.

The oil bearing layers in the subsurface are reminiscent of a sponge. The oil 'hides' in tiny pores and gaps and only some of the oil can be pressed out of the chalk and into the borehole by injecting water into the chalk layer. The rest is left behind as small droplets of oil surrounded by water either in small gaps in the rock or stuck to the walls of the pores. The chalk particles ought to repel oil if they act like particles of the mineral calcite, which chalk is almost 100 per cent made up of.

However the new investigations, carried out with a particularly powerful microscope, have shown that the surfaces of the pores in the chalk are partially covered in a material which oil can stick to.

Hassenkam believes that the surprising behaviour of the material in the surface of the chalk can be explained by studying how the chalk was formed.

"Chalk is actually the casings of ancient algae. The algae gave their cases a type of 'surface coating' to make them resistant to water. And it is probably this surface coating that we can see in action here, even 60 million years later."

For two years now Maersk Oil and Gas and the Danish National Advanced Technology Foundation have been supporting a closely-related project: the Nano-Chalk Venture.