Company News Industry News

- Contact:Minister Xu

- Mobile:13841408476

- Tel:024-44837288

- Fax:024-44837004

- E-mail:xuming58@126.com

- Web:natashaterry.com

- Address:No.110 XiangHuai Road

Benxi Economic Development Zone

Liaoning Province

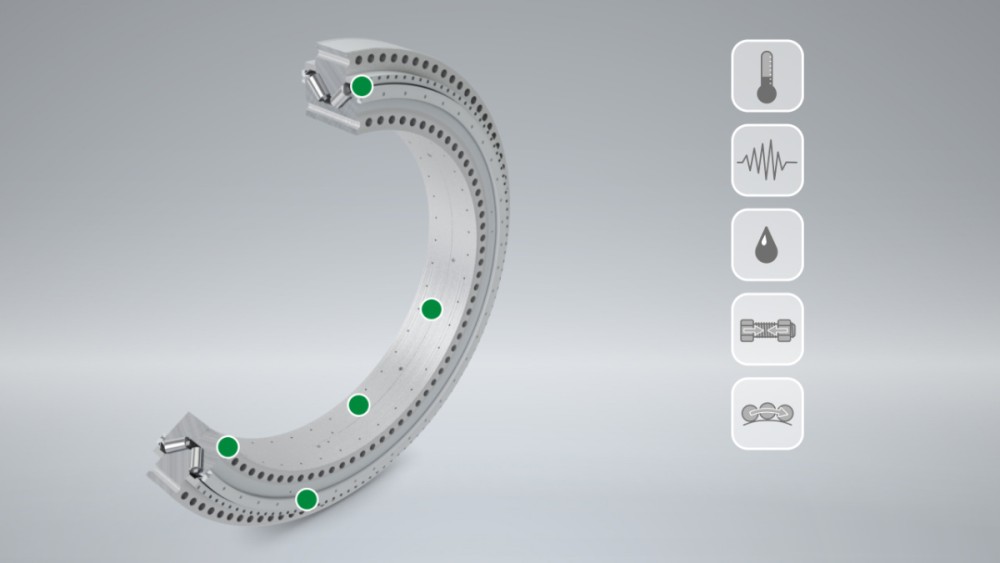

Varied monitoring for rotor bearings: recognize critical operating conditions, avoid bearing damage and reduce operating costs

10 Oct,2018 Schaeffler now offers its FAG rotor flange bearing as a coordinated system consisting of bearing unit, lubricant and sensor technology.

In order to further improve the rolling bearings in the drive train and the overall system and to optimize plant operation, real operating data offer great potential. For example, by evaluating and interpreting the collected data, safety factors can be more accurately determined and adapted for new developments. In addition, Schaeffler is developing sensor concepts with pilot customers in order to be able to record relevant factors influencing damage mechanisms at warehouses that are not yet monitored.

For the rotor flange bearing, for example, such a sensor combination consists of already established temperature and vibration sensors as well as the grease sensor Schaeffler GreaseCheck, the new Schaeffler LoadSense pin and a likewise new roller set slide-way sensor.

Schaeffler GreaseCheck grease sensor The

Schaeffler GreaseCheck is an optical sensor system with which changes in the grease state can be detected at an early stage. The sensor head with only 5mm diameter detects the three parameters turbidity, water content and temperature of the fat. By setting individual thresholds for turbidity and water content, customers can classify the condition of the grease into good or bad during operation. Of particular benefit: With Schaeffler GreaseCheck, wind farm operators can dispense with the time-consuming procedure of taking and measuring grease samples to determine relubrication intervals on new plants. By permanently monitoring the grease condition, operators can respond to changes in the lubricant with maintenance, possibly even before damage has occurred to the bearing. If enough systems are installed, the possibility arises in the medium term to set the relubrication intervals according to demand and thus save even more maintenance.

Schaeffler LoadSense pin for bearing preload monitoring

For rotor bearing systems which are flange- mounted to the surrounding construction, the preload of the screw connections used for this purpose has a direct influence on the performance and service life of the bearing, as they influence the load distribution in the bearing. Schaeffler developed the so-called LoadSense pin for monitoring this bolt preload. This new sensor is based on the Sensotect thin-film sensor system and uses the measuring method of strain gauges. In the case of the load-sense pin, this sensor is coated directly on the front side and, for temperature compensation, also on the outer surface of a small steel cylinder. The sensor is pressed with slight oversize into a bore of the component to be measured and thus experiences the same strain as the surrounding material. In contrast to the known glued strain gauges, the LoadSense pin is therefore inserted directly into the bearing ring.

With the LoadSense pin, Schaeffler is able to monitor the preload of the screw connection of the flange bearing during operation so that the screws can be tightened as required. There is no need to check the preload at fixed intervals. The reliability of the storage system is increased and maintenance costs are reduced.

Roller set slide-way

sensor as an indicator of unfavorable operating conditions at the rotor bearing The inductive sensor counts how often a rolling element passes the sensor head for a fixed number of rotor shaft revolutions. The rolling process of the contact partners in the bearing always includes - if correctly designed - small sliding operations. This micro-slip, between driven bearing ring and rolling element set, changes the peripheral speed of the rolling element set and thus also the frequency of how often a rolling element passes the sensor head. In known Wälzlagerinnengeometrie then the average Gleitweg and micro-slip can be calculated very accurately averaged even with fluctuating rotor speed from the number of rolling elements passed and thus closed back to different load, friction and lubrication conditions. The measurement is simple, extremely reliable and allows conclusions about operating conditions (among other things with regard to the kinematics) of the rolling bearing.

Competitive advantages for pilot

customers Within the scope of these development projects, pilot customers have the opportunity with Schaeffler to determine the critical influencing factors for the rotor bearings on the basis of the measured data. Apart from the medium-term goal to be able to predict defined damage mechanisms in rotor bearings, it is already possible with this sensor combination to recognize several unfavorable operating conditions in the warehouse and to avoid them via an adapted maintenance and operating strategy or to initiate countermeasures at an early stage. Likewise unfavorable conditions are recognized for the bearing, which can be remedied for example by relubrication before bearing damage begins. In this way, the useful lives of the rotor bearings can be increased shortly after installation and the operating costs can be reduced.